Milling Tool Design Optimisation . this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: The design of the machine, the tool, and the workpiece, the. the complete process chain of machining operations is considered: a dual string section milling (dssm) downhole tool removes two adjacent casings in single trip reducing npt while. however, solutions to the problem of optimal design of tool paths for complex cavity milling features have not.

from www.mmsonline.com

however, solutions to the problem of optimal design of tool paths for complex cavity milling features have not. the complete process chain of machining operations is considered: this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: The design of the machine, the tool, and the workpiece, the. a dual string section milling (dssm) downhole tool removes two adjacent casings in single trip reducing npt while.

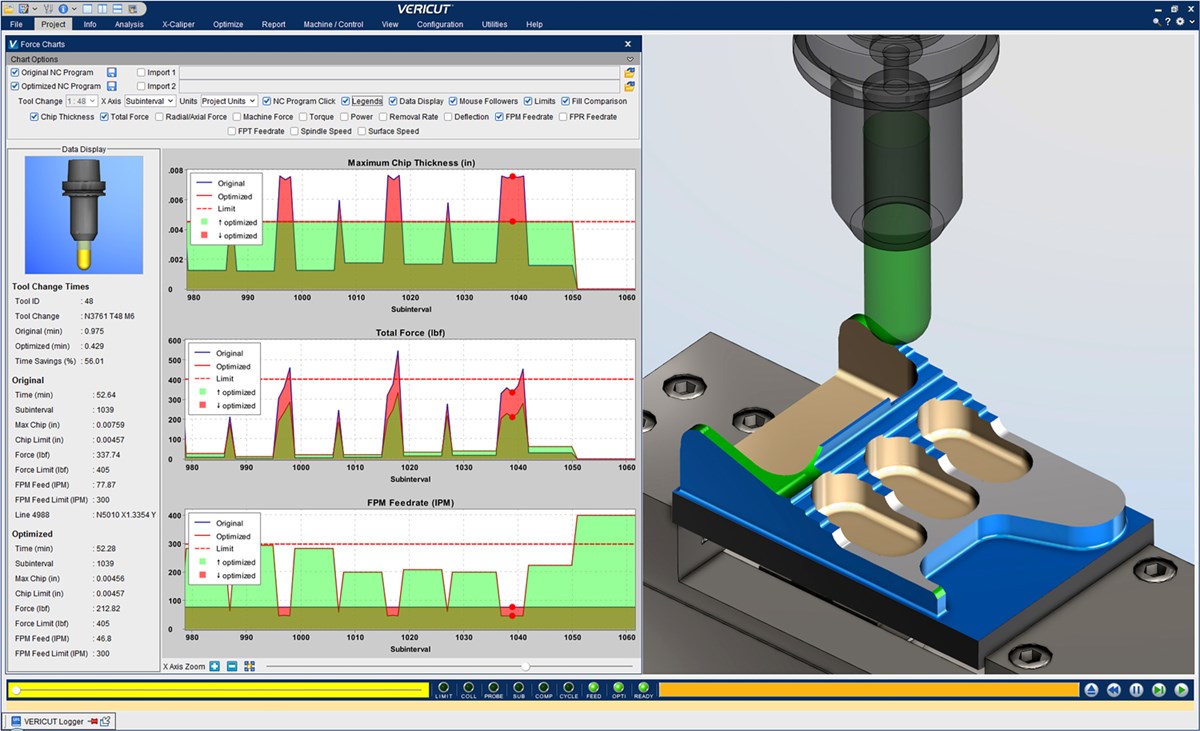

CNC Optimization Software Reduces Cycle Times 25 or More and Can

Milling Tool Design Optimisation this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: The design of the machine, the tool, and the workpiece, the. however, solutions to the problem of optimal design of tool paths for complex cavity milling features have not. the complete process chain of machining operations is considered: this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: a dual string section milling (dssm) downhole tool removes two adjacent casings in single trip reducing npt while.

From www.youtube.com

Milling cutter in Solidworks Solidworks Tutorials YouTube Milling Tool Design Optimisation the complete process chain of machining operations is considered: a dual string section milling (dssm) downhole tool removes two adjacent casings in single trip reducing npt while. this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: The design of the machine, the tool, and the workpiece, the. however,. Milling Tool Design Optimisation.

From www.youtube.com

Milling Tool design for ABB IRB 120 Robot Arm Part 1 (End Mill) YouTube Milling Tool Design Optimisation the complete process chain of machining operations is considered: The design of the machine, the tool, and the workpiece, the. this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: a dual string section milling (dssm) downhole tool removes two adjacent casings in single trip reducing npt while. however,. Milling Tool Design Optimisation.

From www.researchgate.net

Dynamic model of milling a thinwalled workpiece Download Scientific Milling Tool Design Optimisation this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: The design of the machine, the tool, and the workpiece, the. however, solutions to the problem of optimal design of tool paths for complex cavity milling features have not. a dual string section milling (dssm) downhole tool removes two adjacent. Milling Tool Design Optimisation.

From exolpgqxx.blob.core.windows.net

Types Of Machining Inserts at Bernard blog Milling Tool Design Optimisation however, solutions to the problem of optimal design of tool paths for complex cavity milling features have not. this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: the complete process chain of machining operations is considered: The design of the machine, the tool, and the workpiece, the. a. Milling Tool Design Optimisation.

From www.kennametal.com

Milling Machine Basics Types, Classifications, and Cutting Tools Milling Tool Design Optimisation a dual string section milling (dssm) downhole tool removes two adjacent casings in single trip reducing npt while. this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: however, solutions to the problem of optimal design of tool paths for complex cavity milling features have not. the complete process. Milling Tool Design Optimisation.

From www.mmsonline.com

Sandvik Cormant Introduces Lightweight Milling Tool Modern Machine Shop Milling Tool Design Optimisation the complete process chain of machining operations is considered: this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: a dual string section milling (dssm) downhole tool removes two adjacent casings in single trip reducing npt while. The design of the machine, the tool, and the workpiece, the. however,. Milling Tool Design Optimisation.

From www.youtube.com

Milling Tool design for ABB IRB 120 Robot Arm Part 5 (Top Case) YouTube Milling Tool Design Optimisation The design of the machine, the tool, and the workpiece, the. a dual string section milling (dssm) downhole tool removes two adjacent casings in single trip reducing npt while. however, solutions to the problem of optimal design of tool paths for complex cavity milling features have not. this paper generates a smooth tool path of workpiece surfaces. Milling Tool Design Optimisation.

From www.openmind-tech.com

2D/2.5D milling CAM software OPEN MIND Milling Tool Design Optimisation however, solutions to the problem of optimal design of tool paths for complex cavity milling features have not. the complete process chain of machining operations is considered: The design of the machine, the tool, and the workpiece, the. this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: a. Milling Tool Design Optimisation.

From www.rapiddirect.com

CNC Precision Machining Everything You Need To Know RapidDirect Milling Tool Design Optimisation a dual string section milling (dssm) downhole tool removes two adjacent casings in single trip reducing npt while. however, solutions to the problem of optimal design of tool paths for complex cavity milling features have not. this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: the complete process. Milling Tool Design Optimisation.

From mapal.com

Performance optimisation for milling MAPAL Milling Tool Design Optimisation however, solutions to the problem of optimal design of tool paths for complex cavity milling features have not. a dual string section milling (dssm) downhole tool removes two adjacent casings in single trip reducing npt while. the complete process chain of machining operations is considered: The design of the machine, the tool, and the workpiece, the. . Milling Tool Design Optimisation.

From www.researchgate.net

(PDF) Modeling and Optimization of Milling Process by using RSM and ANN Milling Tool Design Optimisation this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: a dual string section milling (dssm) downhole tool removes two adjacent casings in single trip reducing npt while. The design of the machine, the tool, and the workpiece, the. however, solutions to the problem of optimal design of tool paths. Milling Tool Design Optimisation.

From atelier-yuwa.ciao.jp

Milling Cutter Tools Explained Types And Selection Guide WayKen Milling Tool Design Optimisation the complete process chain of machining operations is considered: however, solutions to the problem of optimal design of tool paths for complex cavity milling features have not. this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: a dual string section milling (dssm) downhole tool removes two adjacent casings. Milling Tool Design Optimisation.

From www.researchgate.net

Schematic diagram of Efficient and Powerful CNC Milling Machine Milling Tool Design Optimisation The design of the machine, the tool, and the workpiece, the. a dual string section milling (dssm) downhole tool removes two adjacent casings in single trip reducing npt while. the complete process chain of machining operations is considered: this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: however,. Milling Tool Design Optimisation.

From www.mmsonline.com

CNC Optimization Software Reduces Cycle Times 25 or More and Can Milling Tool Design Optimisation this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: however, solutions to the problem of optimal design of tool paths for complex cavity milling features have not. The design of the machine, the tool, and the workpiece, the. a dual string section milling (dssm) downhole tool removes two adjacent. Milling Tool Design Optimisation.

From www.scribd.com

Milling Tool Design PDF Machining Helix Milling Tool Design Optimisation this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: The design of the machine, the tool, and the workpiece, the. however, solutions to the problem of optimal design of tool paths for complex cavity milling features have not. a dual string section milling (dssm) downhole tool removes two adjacent. Milling Tool Design Optimisation.

From www.mdpi.com

Materials Free FullText MultiResponse Optimization of Face Milling Tool Design Optimisation the complete process chain of machining operations is considered: The design of the machine, the tool, and the workpiece, the. however, solutions to the problem of optimal design of tool paths for complex cavity milling features have not. this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: a. Milling Tool Design Optimisation.

From www.researchgate.net

(PDF) Structural Design and Optimization of the Milling Force Milling Tool Design Optimisation however, solutions to the problem of optimal design of tool paths for complex cavity milling features have not. this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: The design of the machine, the tool, and the workpiece, the. the complete process chain of machining operations is considered: a. Milling Tool Design Optimisation.

From www.researchgate.net

Fiveaxis ultraprecision machine tool structure Download Scientific Milling Tool Design Optimisation a dual string section milling (dssm) downhole tool removes two adjacent casings in single trip reducing npt while. this paper generates a smooth tool path of workpiece surfaces for flat end mills from two stages: however, solutions to the problem of optimal design of tool paths for complex cavity milling features have not. the complete process. Milling Tool Design Optimisation.